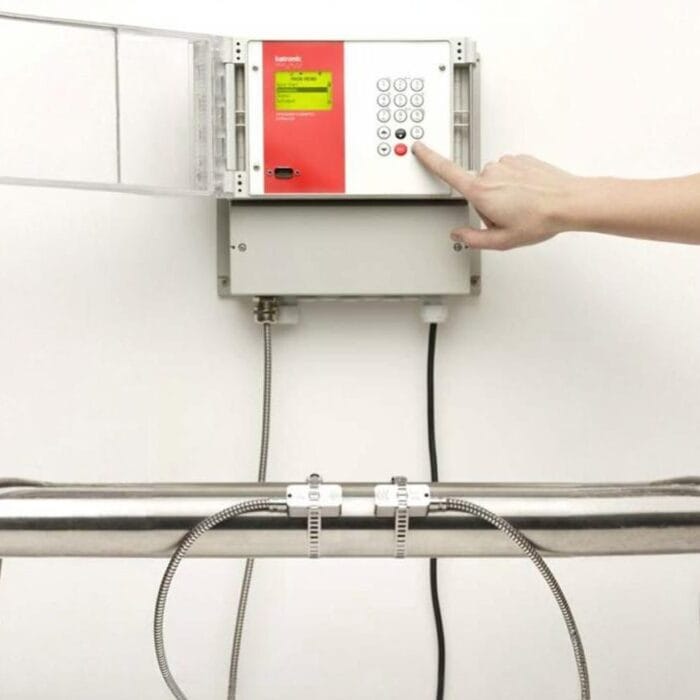

KATflow 150 Ultrasonic Flowmeter

Sabit Ölçüm Noktaları İçin Yüksek Performanslı Çözüm

KATflow 150, sabit kurulumlarda üstün doğruluk ve güvenilirlik sağlayan, kompakt yapılı bir ultrasonik debimetredir. Endüstriyel tesislerde sürekli akış takibi, proses kontrolü ve enerji yönetimi gibi uygulamalar için özel olarak tasarlanmıştır. Temassız sensör teknolojisi sayesinde boru sistemine müdahale etmeden kurulur ve çalıştırılır—bu da bakım kolaylığı ve kesintisiz işletme avantajı sunar.

- Tahmini Teslimat : 4-6 hafta

- Depodan Teslim: Hızlı teslimat

KATflow 150 Ultrasonic Flowmeter

Sabit Ölçüm Noktaları İçin Yüksek Performanslı Çözüm

KATflow 150, sabit kurulumlarda üstün doğruluk ve güvenilirlik sağlayan, kompakt yapılı bir ultrasonik debimetredir. Endüstriyel tesislerde sürekli akış takibi, proses kontrolü ve enerji yönetimi gibi uygulamalar için özel olarak tasarlanmıştır. Temassız sensör teknolojisi sayesinde boru sistemine müdahale etmeden kurulur ve çalıştırılır—bu da bakım kolaylığı ve kesintisiz işletme avantajı sunar.

Öne Çıkan Teknik Özellikler

🧠 Gelişmiş DSP Teknolojisi: Kodlu sinyaller ve yüksek örnekleme hızıyla hassas veri analizi

🌡️ Geniş Sıcaklık ve Debi Aralığı: Sıcak, soğuk, temiz veya kirli sıvılarda kesintisiz ölçüm

🔒 IP66 / IP67 Korumalı Gövde: Zorlu endüstriyel ortamlarda güvenle kullanılabilir

📟 4-20 mA, Modbus, HART Desteği: SCADA ve otomasyon sistemleri ile entegrasyon kolaylığı

🔍 Gelişmiş Diagnostik Ekranı: Akış, sinyal durumu ve hata raporlamalarını anlık izleyin

🔧 Kolay Kalibrasyon ve Ayar: Kullanıcı dostu menü sistemi ile hızlı devreye alma

Uygulama Alanları

✅ Proses kontrol sistemleri

✅ Su ve atık su yönetimi

✅ Gıda, kimya ve ilaç endüstrisi

✅ Enerji üretimi ve tüketim analizleri

✅ Isıtma-soğutma sistemleri (HVAC)

Broşürler

TR – EN